The hidden storage

underneath the mattress in your motorhome is a great place to stash extra gear, seasonal

blankets and clothing, and in our family, extra fly-fishing and horseback-riding

equipment. The task of holding up the

mattress and bed platform while hunting for a particular item is relegated to

hydraulic struts that can be overwhelmed by the sheer weight of the bed

system — and end up bopping one on the head as gravity pulls it down.

Hatchlift has made a science out of properly pairing sturdy hydraulic

gas springs (struts) for compartment doors and has banked that experience by

perfecting a similar system for holding up a mattress platform. The company's

Bedlift Kit provides the strength needed to make under-bed storage

practical and convenient.

The Bedlift system is designed to take the effort out of lifting

most beds. There are five kits available, which cover the gamut of mattress

sizes and platform configurations. Beds with smaller front compartments can use

the lighter versions; heavy and large kits are designed for queen-

and king-size beds with access to larger storage areas. Interestingly,

the company places a limitation on exceptionally heavy mattresses,

like extra-thick queens and kings made of memory foam, but in

our case, the heavy Bedlift worked fine with our queen-size mattress, which was

custom made and is much heavier than most beds on the market. Part of

this success is attributed to the moderate-size platform compartment, but most of the credit goes to the stout springs and bulletproof mounting system.

Complete kits come with various style brackets, high-quality springs, wood supports and screws to adapt to any style platform bed, using detailed instructions that show bracket locations for different scenarios. While the instructions are complete, it's important to recognize that not all bed platforms are equal and finding the right spring angle might take some experimentation. Hatchlift also offers an informative installation video on its website that is helpful when planning the installation.Installation time will run roughly one hour and the process is relatively simple for most do-it-yourselfers. Tools required: variable-speed drill and bit, measuring tape, pencil, #2 Phillips screwdriver, 2-by-4-inch lumber that can be cut to the proper length and wood glue or construction adhesive. All gas springs are under high pressure, so care must be exercised during installation, and always wear safety glasses.

To begin the process,

the mattress and all bedding must be in place to ensure proper placement of the

springs. You'll need to cut a length of 2-by-4-inch lumber to support

the platform when making the measurements and installing the

brackets. It's best to enlist the help of another person for

this process. Once the two-by-four is in place, you may need one or two small

wooden stops to keep it from

slipping during installation. We identified our platform configuration

in the instructions and proceeded with the measurements for installing

the lower brackets. Once this was done, the gas springs were attached. From here, the positioning of the upper brackets was estimated and they were

attached to the supplied wood blocks. The springs were then attached to

the upper brackets and the blocks positioned under the bed platform,

marking the location with a pencil. After disconnecting the gas springs

from the upper brackets, we mounted the blocks in place using the supplied 11/4-inch gold-color screws. The springs were then reconnected and the

two-by-four support removed to test Bedlift operation.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

[1] Using the instructions as a guide to identify the platform configuration, measurements are made to locate lower brackets. [2] Pilot holes are drilled into the platform frame and brackets attached [3] using a screw gun. In this case, the backing was solid, so a support was not necessary [4] Blocks of wood are used to attach the upper brackets. [5] Once the position is marked on the blocks, the brackets are screwed in place.

We needed to adjust the upper and lower brackets because our initial test revealed that the bed was too difficult to lift and lower. Once we dialed in the position that worked best, the wood blocks with the upper brackets were removed, glue added and they were reinstalled permanently. The glue or the adhesive should be allowed to dry for at least 24 hours before operating the Bedlift. In our case, the location for the lower brackets provided a solid-wood backing. In some situations, the mounting location might require structural reinforcement using wood blocks.

Operation of the bed platform was effortless after installing the Bedlift and it stayed put until we wanted it lowered. Since the springs come in various sizes, you might even find additional uses for this system, like assisting a laundry hamper door or any interior storage bin that's in need of a little bit of help.

Kits are priced from $46 to $54 and are available at Camping World and other RV retail stores. It's best to check the company's website before ordering, so the right kit can be specified. Hatchlift backs each kit with a 12-month warranty.

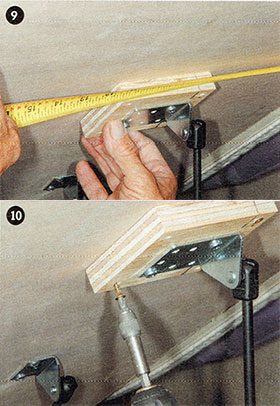

[6] With the help of an assistant, measure the distance specified in the instructions and cut a piece of 2-by-4-inch lumber to hold the platform up during the installation. [7] The gas spring is attached to the upper and lower brackets to determine positioning on the platform. [8] Once established, the spring is disconnected from the upper bracket and the block is predrilled. [9] Measurements are confirmed a second time and then the wood block and bracket [10] are attached to the platform with 11/2-inch gold screws and glue.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)